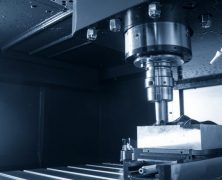

When producing a part or component to exact specifications and without flaws, defects or differences are critical, then using CNC machine services should be a top priority. The technological advances in CNC machine services offered through the best shops in the country have expanded the types of components shops can produce. New equipment types and variations on traditional milling and turning machines have allowed the industry to provide components and parts with incredibly low tolerances, perfect for even the most demanding of industries. Most CNC machine services, especially when it comes to precision machining needs, are done for specific industries. Perhaps the biggest demand for these parts from the best shops comes from the aerospace and aeronautics industries. However, these parts are also in high demand in the automotive, motorsport and firearm industries and with AS9100 and ISO 9001 registration possible with these companies quality control is a key factor in all production. The History The history of CNC machine services goes back further in time than most people assume. The origins of the process and technology began in the mid part of the 1940s. It was, at that time, not CNC or Computer Numerical Control but rather just NC or Numerical Control. These systems were built as a way to control machines to duplicate movements precisely. These originally operated on a cam or a punched type of template, similar to the workings of a player piano. These systems were not very accurate, but they were more precise and faster than completing the machining, turning and milling by hand. From the early stages, further control over the movement of the machines and the tools evolved to provide very specific movements and control over the equipment during the process. Modern Evolution of CNC Machine Services...